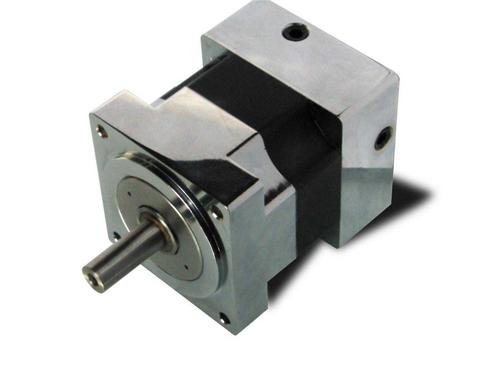

The planetary gearbox is also called the gearbox. Its structure is a mechanism in which multiple planetary gears rotate around a sun gear. It is also a mechanism that reduces the transmission speed ratio while increasing the torque of the motor proportionally.

Features: Compared with similar ordinary tooth physics box, it has smooth transmission, large bearing capacity, large transmission ratio in small space, especially life. If the gear is made of steel, the service life can reach 1000Y, the volume is small and the appearance is beautiful.

Application: Planetary gearbox is widely used. It was originally used in conjunction with the motor. In addition to the miniature reduction motor, it is also used in the sunshade industry, office automation, smart home, production automation, medical equipment, financial machinery, game consoles and other fields. Such as automatic curtains, smart toilets, lifting systems, currency counters, advertising light boxes and other industries.

Planetary gearboxes on the market mainly include straight 16MM, 22MM, 28MM. 32MM, 36MM, 42MM, matched with the motor, its function can reach the load torque: 50KG 1-30W, load speed: 3-2000RPM.

Planetary gearbox is an important component widely used in mechanical transmission. When a pair of gears mesh, due to the unavoidable existence of errors in tooth pitch and tooth profile, meshing shocks will occur during operation, which corresponds to the gear meshing frequency. Noise, friction noise also occurs due to relative sliding between tooth surfaces. Since gears are the basic parts of gearbox transmission, reducing gear noise is necessary to control gearbox noise. Generally speaking, the main causes of gear system noise are as follows:

1. Gear design. Improper parameter selection, too small overlap, improper or no modification of the tooth profile, unreasonable gear box structure, etc. In terms of gear processing, the base pitch error and tooth profile error are too large, the tooth side clearance is too large, and the surface roughness is too large.

2. Gear train and gear box. The assembly is eccentric, the contact accuracy is low, the parallelism of the shaft is poor, the rigidity of the shaft, bearing, support is insufficient, the rotation accuracy of the bearing is not high, and the clearance is improper.

3. Other input torque. The fluctuation of load torque, the torsional vibration of the shaft system, the balance of the motor and other transmission pairs, etc.

The difference between a spur gear planetary reducer and a helical gear planetary reduction is: the spur gear planetary carrier can be used as a single support or as a double support. The planet carrier of the helical gear planetary reducer must be supported by a double support structure. The single support of a spur gear is far inferior to the double support of a spur gear. Compared with the helical gear planetary reducer, the double-support spur gear planetary reducer has higher precision than the spur gear, so the helical planetary reducer has higher accuracy and the price is also higher than that of the spur gear planetary reducer. Confidential is more expensive.

Compared with ordinary gear transmission, planetary gear transmission has a series of outstanding advantages when their parts materials and mechanical properties, manufacturing accuracy, working conditions, etc. are the same, so it is often used as a planetary reducer/planetary Gear reducer, speed increaser, differential and reversing mechanism, and other special purposes. The main features of planetary gear transmission are as follows:

(1) The planetary reducer is small in size, light in weight, compact in structure, large in transmission power, and high in load capacity; this feature is determined by the internal factors such as the structure of the planetary gear transmission, as shown in the figure below.

A. The planetary reducer has the principle of power splitting. Several identical planetary gears are evenly distributed around the center wheel to share the load, so that the load on each gear is smaller, and the corresponding gear modulus can be smaller. In the case of uniform load, with the increase of the planetary gear, its external size decreases.

B. The planetary reducer makes reasonable use of internal gearing. Make full use of the high bearing capacity of the internal gear and the space volume of the internal gear (or ring gear), thereby reducing the radial and axial dimensions, making the structure very compact and the bearing capacity high.

C. Planetary reducer is a coaxial transmission device. Each center wheel forms a coaxial transmission, and the input shaft and the output shaft are coaxial, so that the size of the transmission device in the length direction is greatly reduced.

(2) The planetary reducer has a large transmission ratio; as long as the type of planetary transmission and the gear allocation plan are appropriately selected, a few gears can be used to obtain a large transmission ratio. In a planetary mechanism that is not used as a power transmission but mainly used to transmit motion, its transmission ratio can reach several thousand. In addition, because the planetary gear transmission can rotate its three basic components, it can realize the synthesis and decomposition of motion, as well as complex motion such as stepped and continuously variable transmission.

A planetary reducer/planetary gear reducer can obtain a large transmission ratio, but it must be noted that its transmission efficiency will become lower.

(3) The planetary reducer has high transmission efficiency; because the planetary gear transmission adopts a symmetrical split transmission structure, even if it has several evenly distributed planetary gears, the reaction forces acting on the center wheel and the rotating arm bearings are balanced with each other, Conducive to improving transmission efficiency. When the transmission type is selected properly and the structure layout is reasonable, its efficiency can reach 0.97-0.99.

(4) The planetary reducer has stable motion, strong resistance to shock and vibration; due to the use of several identical planetary wheels, evenly distributed around the center wheel, the inertial forces of the planetary wheels and the rotating arm can be balanced with each other. Increase the number of teeth involved in the meshing, so the planetary reducer/planetary gear reducer has smooth transmission motion, strong resistance to shock and vibration, and more reliable work.

china planetary gearbox manufacturers

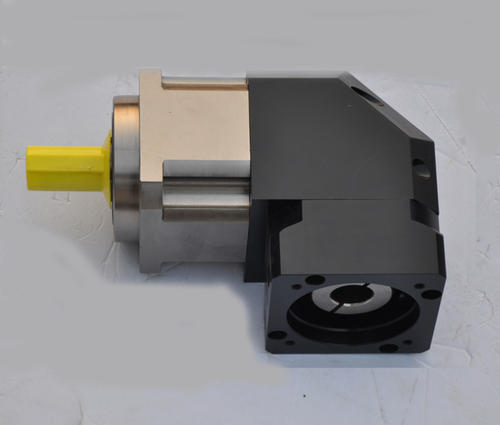

ZF series servo planetary reducer series:

It has the characteristics of high precision, high rigidity, high load, high efficiency, high speed ratio, high life, low inertia, low vibration, low noise, low temperature rise, beautiful appearance, light and small structure, convenient installation, precise positioning and so on. It is suitable for the acceleration and deceleration transmission of AC servo motors, DC servo motors, stepping motors, and hydraulic motors. It is suitable for connecting drive products manufactured by any manufacturer in the world, such as: Panasonic, Delta, Yaskawa, Fuji, Mitsubishi, Sanyo, Siemens, Schneider, Fanuc, Kobe, Kollmorgen, AMK, Parker, etc.

ZE series servo planetary reducer series:

Designed for square flanges, the installation size is simple and convenient. Model points: ZF40, 60, 90, 120, 160, 200 frame models. Speed ratio: 1-1000 has 19 kinds of ratio speeds to choose from; divided into one, two, and three-stage variable reduction transmission; precision: the first-stage transmission accuracy is 6-8 arc minutes, the second-stage transmission accuracy is 8-10 arc minutes, three Grade transmission accuracy is 12-15 arc minutes; more than 1,000 specifications.

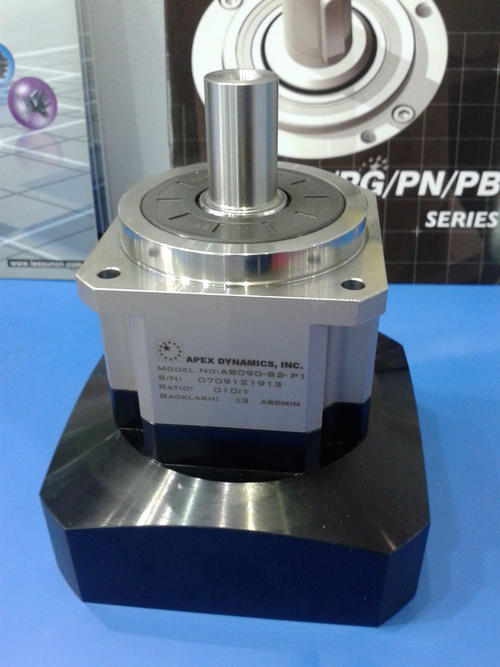

VR series helical gear planetary reducer

Features:

product description

Features:

The reducer is a square type, flange connection, high-precision planetary gear reducer, and adopts a helical gear design. Compared with the previous straight teeth, the gear mesh is smoother and the noise is reduced; high-precision return clearance <3′ , Especially when rotating with low pulsation, it fully demonstrates the superior performance of high-precision servo motors; no maintenance is required, and installation is convenient.

Application areas:

Mainly used in CNC machine tools, machine tool transformation, packaging machinery and military industries.

Technical Parameters:

Reduction ratio: single-stage type: i=3,4,5,6,7,8,9,10;

Two-level type: i=15,20,25,35,45,81;

Motor power: 50W---5000W

Accuracy: VR-S standard accuracy 15′, VR-LB precision type 5-10′, VR-PB high-precision type 3′

The principle of the planetary reducer is a power transmission mechanism that uses a gear speed converter to reduce the number of revolutions of the motor to the required number of revolutions and obtain a larger torque. The gear with fewer teeth on the transmission shaft of the planetary reducer meshes with the large gear on the output shaft to achieve the purpose of deceleration. Ordinary reducers will also have several pairs of gears meshing with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

Uses and characteristics

The planetary reducer is small in size, light in weight, high in load capacity, long in service life, stable in operation and low in noise. It has the characteristics of power splitting and multi-tooth meshing. Applicable to industrial sectors such as lifting and transportation, construction machinery, metallurgy, mining, petrochemical, construction machinery, light industry and textile, medical equipment, instrumentation, automobiles, ships, weapons, aerospace, etc.

Planetary reducer is a new type of planetary reducer with wide versatility. The internal gear adopts low-carbon alloy steel carburizing and quenching plus grinding or nitriding process. The whole machine has the characteristics of small structure size, large output torque, large speed ratio, high efficiency, safe and reliable performance, etc.

Planetary reducer is an industrial product with a wide range of uses. Its performance is comparable to other military-grade reducer products, but it has an industrial-grade product price and is used in a wide range of industrial situations. Planetary reducer reduction ratio: 25~4000r/min, output torque: up to 2600000Nm, motor power: 0.4-12934kW, product installation form: foot installation, flange installation, torque arm installation, shaft output method: solid shaft, Involute spline solid shaft, etc. The planetary gear reducer has a variety of specifications to choose from, including 2 or 3 planetary gears, which can be combined with different types of primary gears. The first-stage gear can be a helical gear, a bevel gear, or a combination of helical and straight teeth. High-quality machining accuracy and finite element analysis of the planetary gear cage optimizes the load distribution on the planetary gear and other contact parts. The planetary gear reducer adopts a modular design, which can be changed and combined according to customer requirements. The reducer adopts involute opening. Linear planetary gear transmission, rational use of internal and external meshing and power splitting. The gears are carburized and quenched or nitrided to obtain a high-hard wear-resistant surface. The gears are ground after heat treatment, which reduces noise and improves the efficiency of the whole machine. And service life. Therefore, it has the characteristics of light weight, small size, large transmission ratio range, high efficiency, stable operation, low noise and strong adaptability.

Performance analysis:

Deceleration ratio: The input speed is higher than the output speed.

Number of stages: the number of sets of planetary gears. Since one set of planetary gears cannot meet the larger transmission ratio, sometimes two or three sets of planetary gears are needed to meet the requirements of users for larger transmission ratios. Due to the increase in the number of planetary gears, the length of the two- or three-machine reduction stage will increase, and the efficiency will decrease.

Full load efficiency: refers to the transmission efficiency of the reducer under the maximum load condition (the output torque is stopped by failure).

Average life: refers to the continuous working time of the reducer under the rated load and the highest input speed.

Rated torque: a standard for reducers. Under this value, when the output speed is 100 rpm, the life of the reducer is the average life. Exceeding this value, the average life of the reducer will be reduced. When the output torque exceeds twice this value, the reducer malfunctions.

Lubrication method: no lubrication is required. The reducer is fully sealed, so there is no need to add grease during the entire service life.

Noise: The unit is decibel (dB). This value is measured when the input speed is 3000 rpm, without load, and one meter away from the reducer.

Return clearance: Fix the output end and rotate the input end clockwise and counterclockwise to make the output end produce rated torque +-2% torque, there is a slight angular displacement at the input end of the reducer, and this angular displacement is the return clearance. The unit is "cent", which is one-sixtieth of a degree. The return clearance value given in this manual refers to the output end of the reducer.